This website stores cookies on your computer. These cookies are used to improve your website experience and provide more personalized services to you, both on this website and through other media. To find out more about the cookies we use, see our Privacy Policy.

OK

LEAVE AN APPLICATION

We will offer an individual solution for you

By submitting the form, you agree to the Privacy Policy

TANK

— AISI 316

— PP

— PP

FILLING METHODS

Coriolis flow meter:

— weight type of measurement;

— filling accuracy ±0,15%;

— wide scope of application.

— weight type of measurement;

— filling accuracy ±0,15%;

— wide scope of application.

Electromagnetic flow meter:

— volumetric type of measurement;

— filling accuracy ±0,15%;

— corrosion resistance.

— volumetric type of measurement;

— filling accuracy ±0,15%;

— corrosion resistance.

By time:

— low price and maintenance cost;

— corrosion resistance;

— no stagnant zones.

— low price and maintenance cost;

— corrosion resistance;

— no stagnant zones.

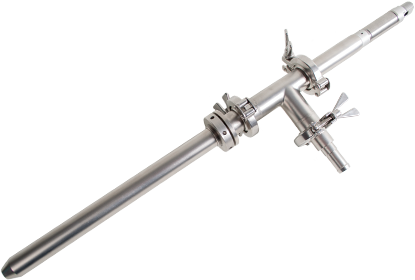

BOTTOM-CLOSE

— AISI 316

— TT

— TT

ADVANTAGES

Recipe readjustment is time saving

Wide dosing range — from 100 ml to 20l

Corrosion-resistant performance — polypropylene PP or titanium Ti

Reliability — simple design of dosing mechanisms

High accuracy (use of Krohne flow meters or Endress+Hauser)

No stagnant zones (use of Krohne flow meters)

Easy equipment cleaning — (automatic cleaning system with cleaning spinners inside the tank)

Minimal maintenance, no wearing parts

Wide range of dose adjustment

Wide range of dosed products

Security system (door lock system)

Intuitive machine interface

Wide dosing range — from 100 ml to 20l

Corrosion-resistant performance — polypropylene PP or titanium Ti

Reliability — simple design of dosing mechanisms

High accuracy (use of Krohne flow meters or Endress+Hauser)

No stagnant zones (use of Krohne flow meters)

Easy equipment cleaning — (automatic cleaning system with cleaning spinners inside the tank)

Minimal maintenance, no wearing parts

Wide range of dose adjustment

Wide range of dosed products

Security system (door lock system)

Intuitive machine interface

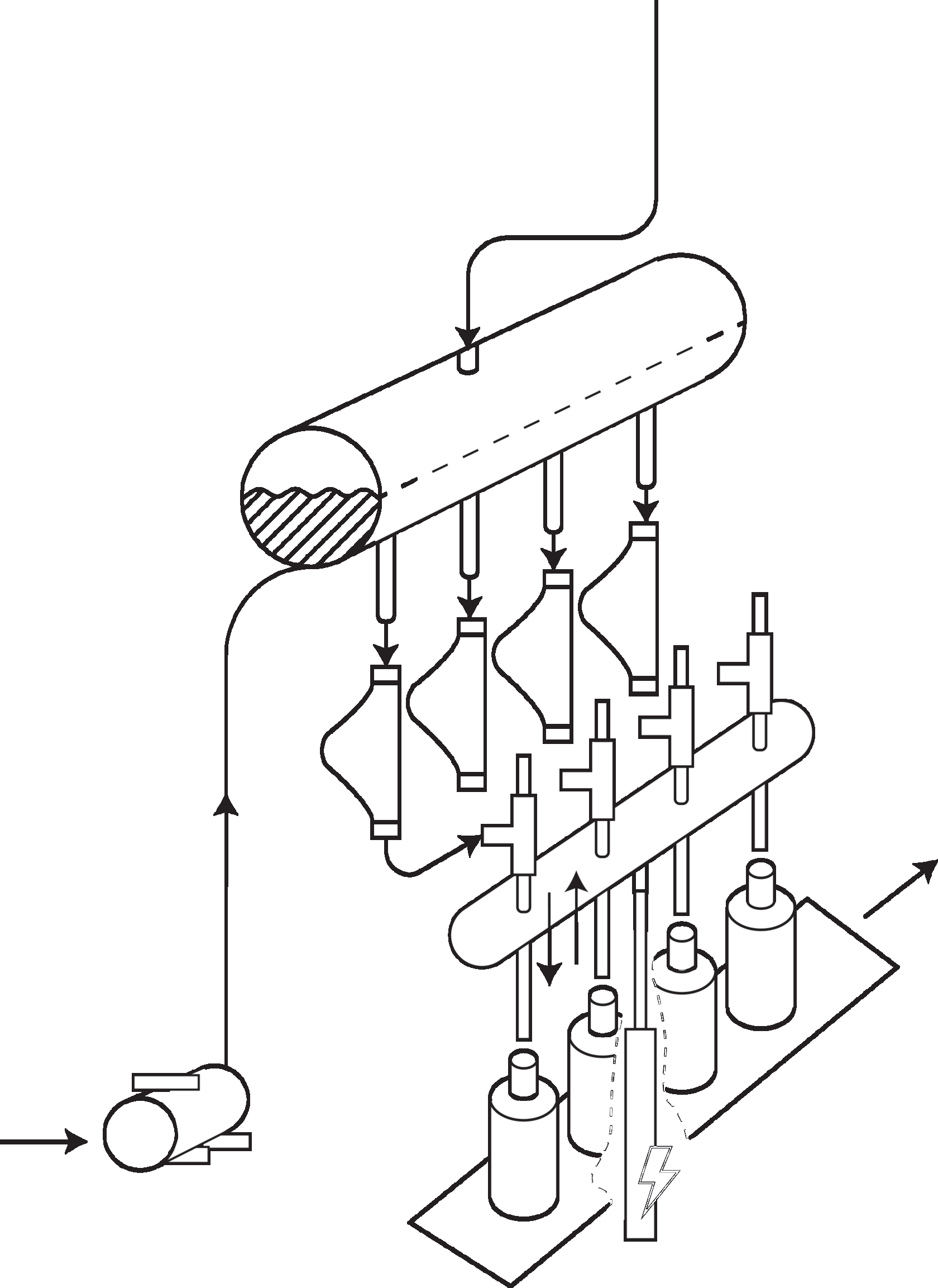

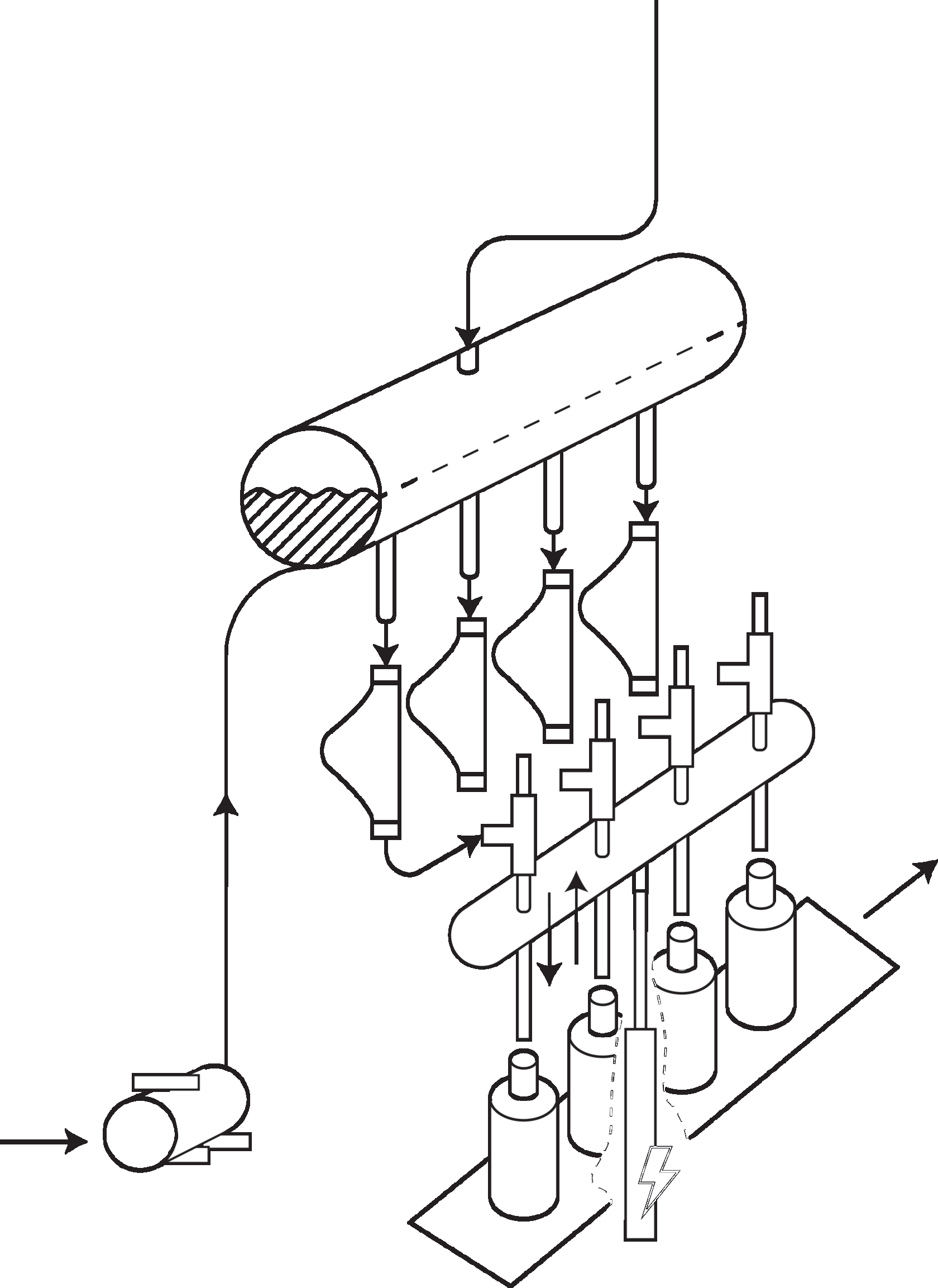

OPERATION CONCEPT

Membrane pump 1 uploads the filling product into the transfer tank 2.

In tank 2, the overpressure and the preset level of the product are automatically supported by the valve system and level sensors.

The excessive pressure is created by compressed air or inert gas.

The product is supplied to the consumer container from

the transfer tank 2 through flow meters 3 and nozzles with bottom-close 4.

The electric cylinder 5 lifts the nozzles 4 according to the

programmed algorithm considering the container geometry and product properties.

The industrial controller synchronizes the algorithm of lifting the nozzles with the product feed mode.

The settings for each type of container and product are saved as recipes. When readjusting, the recipes are applied in one click.

In tank 2, the overpressure and the preset level of the product are automatically supported by the valve system and level sensors.

The excessive pressure is created by compressed air or inert gas.

The product is supplied to the consumer container from

the transfer tank 2 through flow meters 3 and nozzles with bottom-close 4.

The electric cylinder 5 lifts the nozzles 4 according to the

programmed algorithm considering the container geometry and product properties.

The industrial controller synchronizes the algorithm of lifting the nozzles with the product feed mode.

The settings for each type of container and product are saved as recipes. When readjusting, the recipes are applied in one click.

SMART FILLING SYSTEM — is a filling system with the setting of the dosing modes, which remembers and applies the parameters in one click at a readjustment.

Pressure maintenance

±0.05% Bar

±0.05% Bar

SMART FILLING SYSTEM TECHNOLOGY

QUICK READJUSTMENT – IS COST SAVING!

QUICKLY

DO NOT

DO NOT

remove the nozzle

fill with liquid

For high capacity

SLOWLY

remove the nozzle

fill with liquid

To prevent foaming and splashing out of the product

QUICKLY

remove the nozzle

fill with liquid

For high capacity

SLOWLY

DO NOT

DO NOT

fill with liquid

lift the nozzle

To prevent foaming

HIGH CAPACITY

WITHOUT FOAMING

AND SPLASHING OUT

WITHOUT FOAMING

AND SPLASHING OUT

Smart Filling Systems is a filling system with flexible settings for the speed of filling with liquid and lifting the nozzle for four stages of dosing.

Four stages of dosing are enough but it is possible to increase the number for containers of complicated form.

To reduce vibration smooth acceleration of the speed of lifting and lowering the nozzle is used.

Four stages of dosing are enough but it is possible to increase the number for containers of complicated form.

To reduce vibration smooth acceleration of the speed of lifting and lowering the nozzle is used.

START OF CYCLE

ROUGH FILLING

PRECISE FILLING

END OF CYCLE

END OF CYCLE

PRECISE FILLING

ROUGH FILLING

START OF CYCLE

LEAVE A REQUEST

We will offer an individual solution for you

When you submit the form, you accept the Privacy Policy.

STANDARD BLOCKS

Additional

information

information