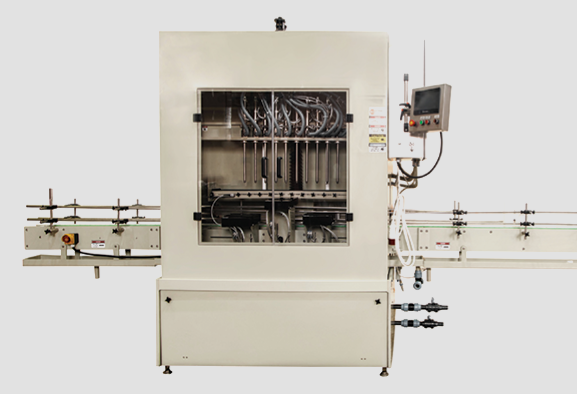

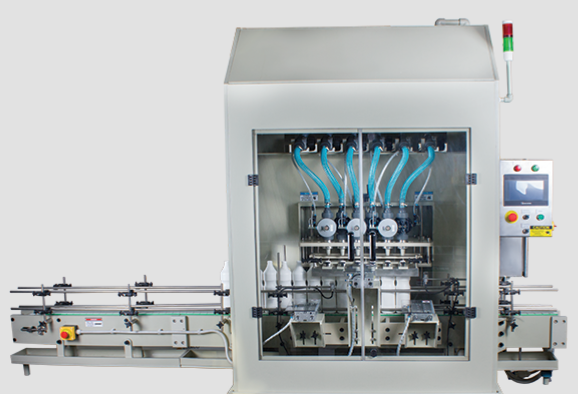

TRANSFER TANK

It provides filling conditions constancy, equipped with:

— automatic product level control system;

— automatic pressure maintenance system;

— automatic cleaning system.

— automatic product level control system;

— automatic pressure maintenance system;

— automatic cleaning system.

DROP CATCHER

It excludes product getting onto the containers external face.

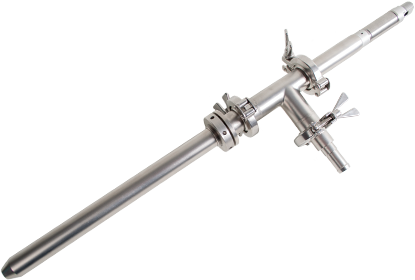

LIFTING NOZZELS MECHANISM

It is manufactured on the basis of electrocylinder according to the Smart

Filling Technology / quick readjustment.

Filling Technology / quick readjustment.

NOZZLES

They prevent the product from dripping / quantity from 2 to 16 pcs, Ti or AISI 316 materials.

CONTROL PANEL

It is a touch panel with intuitive interface.

SAFETY SYSTEM

Door lock system. Provides operator safety during equipment operation.

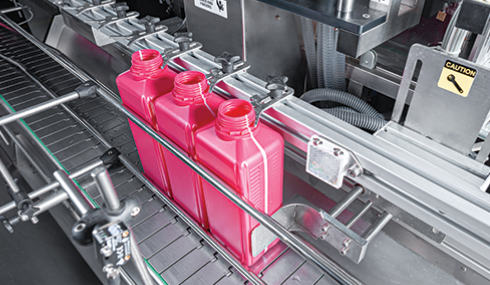

CONTAINERS POSITIONING UNIT

It provides automatic position of the container neck against nozzels.

— on the basis of Khrohne

or Endress+Hauser flow meters;

— by time.

or Endress+Hauser flow meters;

— by time.

FILLING UNIT

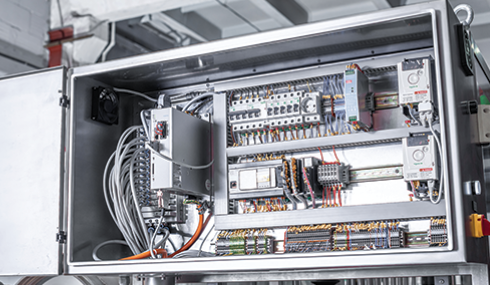

CONTROL BOX

It is made of stainless steel IP54.

It includes controller and automation logic control elements.

It includes controller and automation logic control elements.

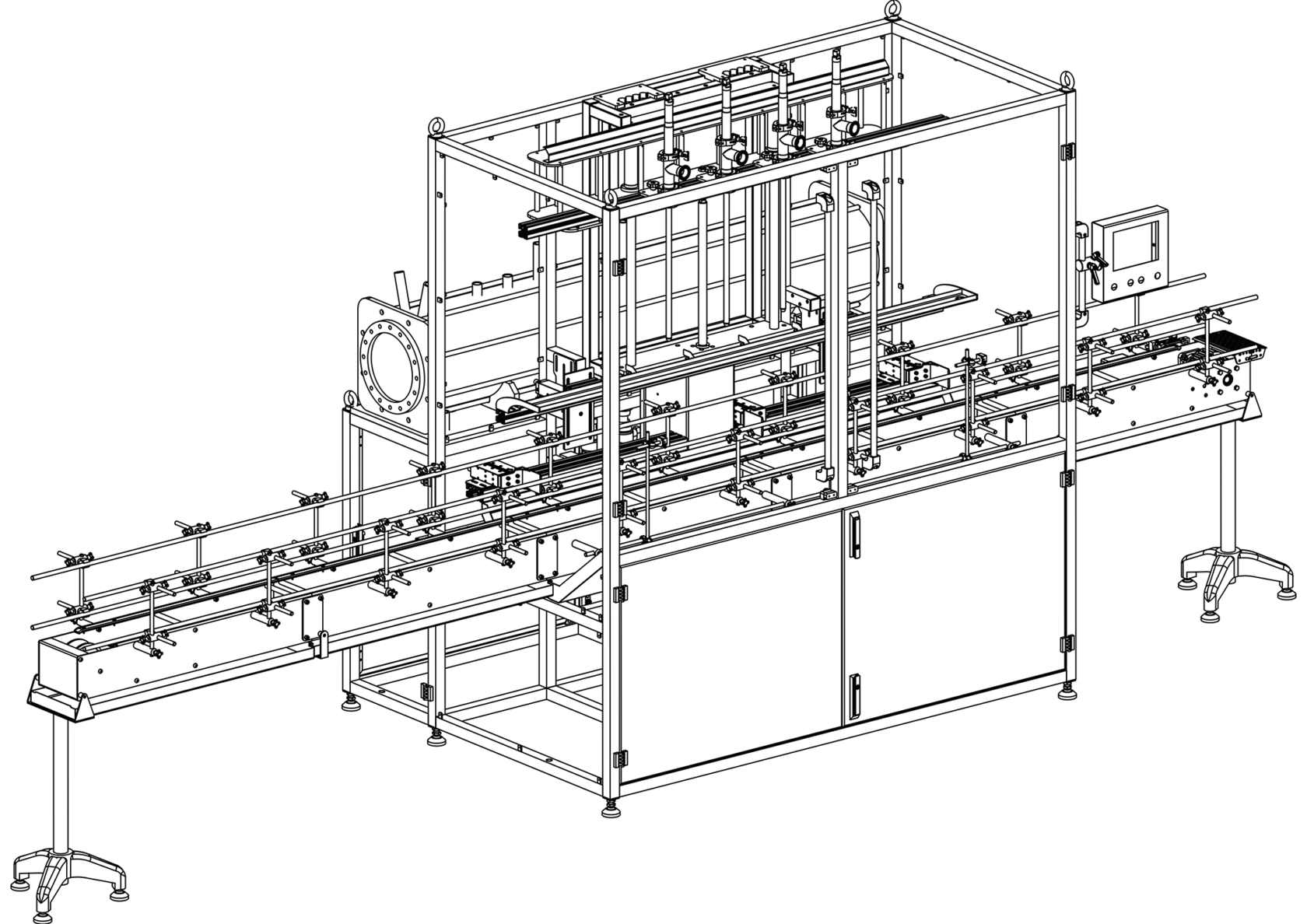

SPECIFICATIONS:

It is used to fill liquid products

to the consumer container.

to the consumer container.

Filling method:

— flow meter Coriolis / electromagnetic;

— by time.

Capacity: up to 60 cpm (500 ml)

Dosage range: 100-20000 ml

Accuracy:

— by time ±1,5%

— flow meter ±0,5%

Transfer tank volume: up to 500 l

Compressed air pressure: 6-8 bar

Compressed air flow: up to 1 800 l/m

Power supply:

— voltage: 380 V

— frequency: 50 Hz

Power consumptionr: up to 1,5 kW

Overall dimensions: L4000xW1600xH2500 mm

Weight: up to 1000 kg

Wetted parts materials:

AISI 304, AISI 316, PP, TI, PA, NBR, PVC.

— flow meter Coriolis / electromagnetic;

— by time.

Capacity: up to 60 cpm (500 ml)

Dosage range: 100-20000 ml

Accuracy:

— by time ±1,5%

— flow meter ±0,5%

Transfer tank volume: up to 500 l

Compressed air pressure: 6-8 bar

Compressed air flow: up to 1 800 l/m

Power supply:

— voltage: 380 V

— frequency: 50 Hz

Power consumptionr: up to 1,5 kW

Overall dimensions: L4000xW1600xH2500 mm

Weight: up to 1000 kg

Wetted parts materials:

AISI 304, AISI 316, PP, TI, PA, NBR, PVC.

ADVANTAGES:

— High accuracy (use of Krohne flow meters)

— Quick readjustment Smart Filling System (readjustment by recipe)

— No stagnant zones (use of Krohne or Endress+Hauser flow meters);

— Easy equipment cleaning (automatic cleaning system with cleaning spinners inside the tank);

— Minimal maintenance, no wearing parts;

— Wide range of dose adjustment;

— Wide range of dosed products;

— Security system (door lock system);

— Intuitive machine interface.

— Quick readjustment Smart Filling System (readjustment by recipe)

— No stagnant zones (use of Krohne or Endress+Hauser flow meters);

— Easy equipment cleaning (automatic cleaning system with cleaning spinners inside the tank);

— Minimal maintenance, no wearing parts;

— Wide range of dose adjustment;

— Wide range of dosed products;

— Security system (door lock system);

— Intuitive machine interface.

AUTOMATIC FILLING UNIT

SMART FILLING TECHNOLOGY