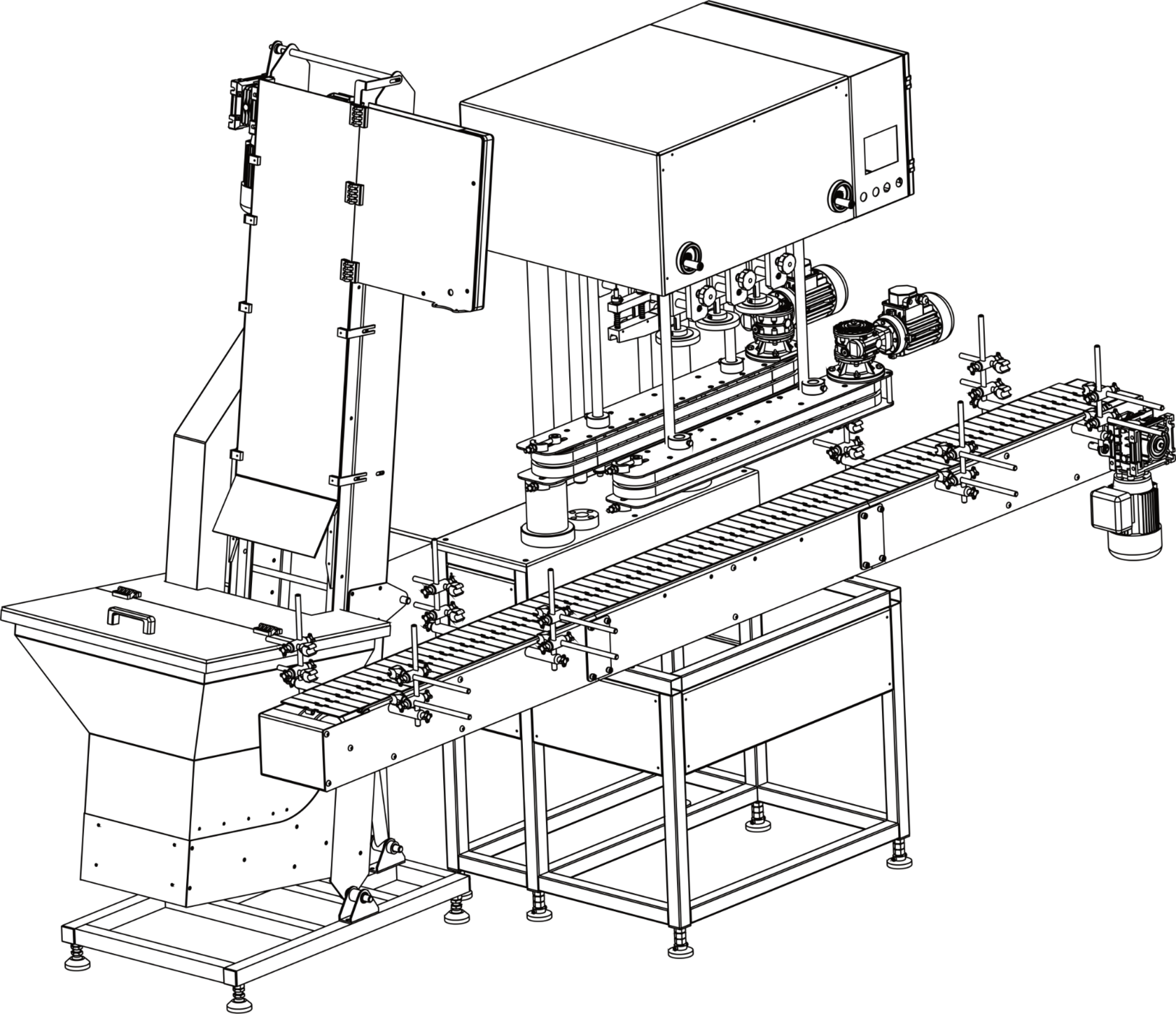

CAP POSITIONING SYSTEM

It is intended for automatic orientation of a cap before installation on a container neck.

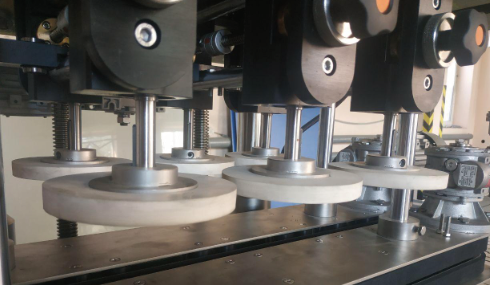

TIGHTETING UP UNIT

Its structure makes it possible to tighten such caps as triger, push-pool, disperser, flat caps, etc.

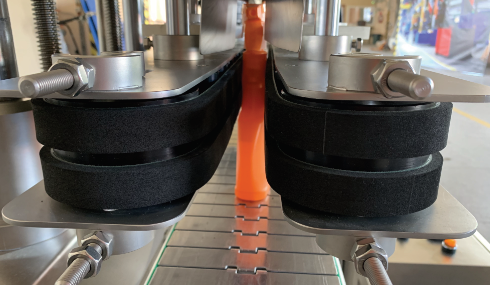

HOLDING BELTS

Holding Belt design allows to use this machine with a wide range of containers: PP, PVC, PET, glass.

CONTROL BOX

It is made of stainless steel IP54. It includes controller and automation logic control elements.

CONTROL PANEL

It is a touch panel with intuitive interface.

CONVEYOR

It delivers containers between capping stages.

It is manufactured in two dimension-types in width.

It is manufactured in two dimension-types in width.

SPECIFICATIONS:

Capacity: up to 120 cpm

Container sizes:

— container hight: up to 570 mm

— container diameter: up to 200mm

— cap diameter: 20-100 mm

Power supply:

— voltage: 220 V

— frequency: 50 Hz

Power consumption: up to 2 kW

Overall dimensions: up to L3000xW985xH1750 mm

Weight: 310 kg

Container sizes:

— container hight: up to 570 mm

— container diameter: up to 200mm

— cap diameter: 20-100 mm

Power supply:

— voltage: 220 V

— frequency: 50 Hz

Power consumption: up to 2 kW

Overall dimensions: up to L3000xW985xH1750 mm

Weight: 310 kg

ADVANTAGES:

— Wide range of screw cap sizes;

— High capacity up to 120 cpm;

— Availability to tighten such caps as push pool, trigger, disperser, flat caps, etc.;

— A wide range of containers types: PVC, PET, glass.

— High capacity up to 120 cpm;

— Availability to tighten such caps as push pool, trigger, disperser, flat caps, etc.;

— A wide range of containers types: PVC, PET, glass.

It is used to tighten most types of caps at the large range of containers.

AUTOMATIC FLOW CAPPING MACHINE