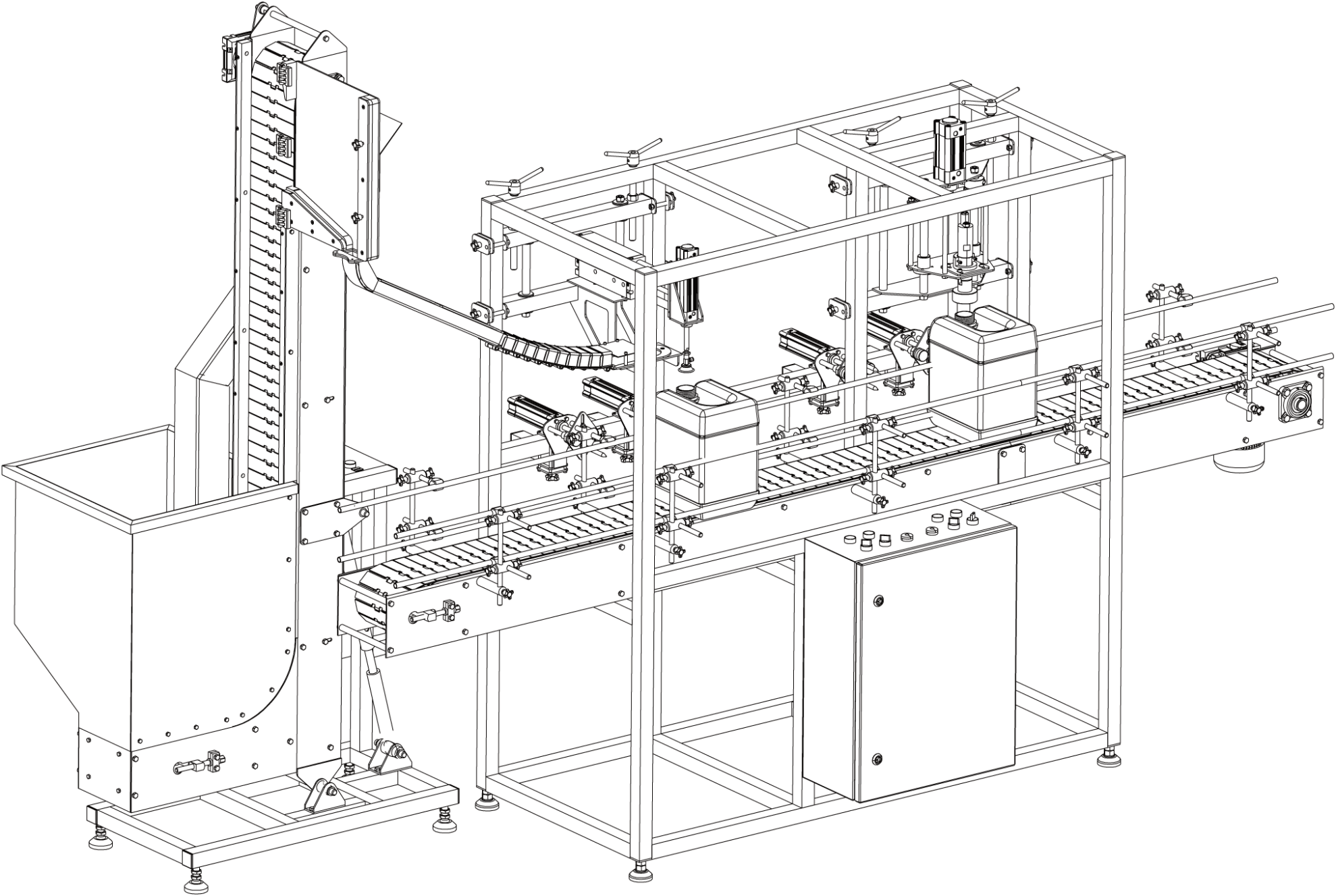

CAP SUPPLYING SYSTEM

It is intended for the installation of a cap on a container neck.

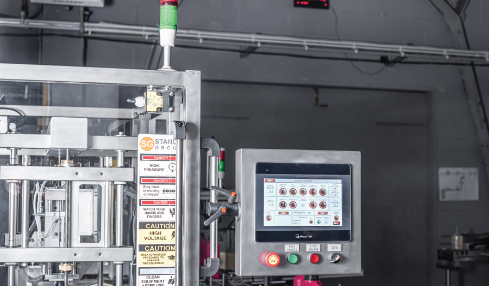

SAFETY SYSTEM

Door lock system provides operator safety during equipment operation.

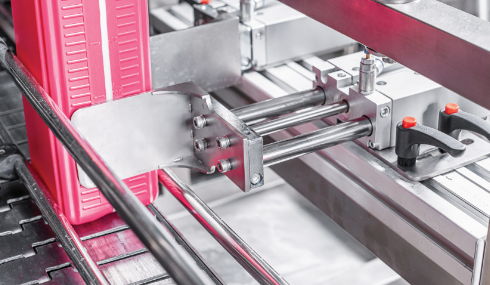

CONTAINERS POSITIONING UNIT

It provides automatic container positioning against operating units.

CONTROL BOX

It is made of stainless steel IP54. It includes controller and automation logic control elements.

CONTROL PANEL

It is a touch panel with intuitive interface.

CONVEYOR

It delivers containers between capping stages. It is manufactured in two dimension-types in width.

SPECIFICATIONS:

Capacity: up to 24 cpm

Compressed air pressure: 6-8 bar

Compressed air flow: up to 250 l/m

Power supply:

— voltage: 380 V

— frequency: 50 Hz

Power consumption: up to 2 kW

Overall dimensions: L3000xW3000xH2500 mm

Weight: up to 300 kg

Materials: AISI 304, PA, NBR, PVC.

Compressed air pressure: 6-8 bar

Compressed air flow: up to 250 l/m

Power supply:

— voltage: 380 V

— frequency: 50 Hz

Power consumption: up to 2 kW

Overall dimensions: L3000xW3000xH2500 mm

Weight: up to 300 kg

Materials: AISI 304, PA, NBR, PVC.

ADVANTAGES:

— Tightening force control

— A wide range of containers

— A wide range of caps

— Adjusting the force on line

— Security system

— Door lock system

— The availability to set the automatic cap positioning

— A wide range of containers

— A wide range of caps

— Adjusting the force on line

— Security system

— Door lock system

— The availability to set the automatic cap positioning

It is used for automatic supplying of a screw cap and tightening it with a certain force. This machine is used for caps that might be installed only vertically.

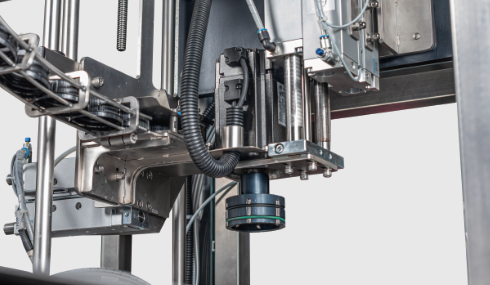

CAP TIGHTNER

It is intended for automatic orientation of a cap before installation on a container neck.

CAP POSITIONING SYSTEM

It tightens caps at the container neck with a certain force. Depending on caps assortment one may use changeable tightners. It may be equipped with the induction sealer.

AUTOMATIC CAPPING MACHINE