INTERMEDIATE TANK

ensures a consistency of conditions, is equipped with:

— the system for automatic product level control;

—#nbspautomatic pressure control system;

— automatic washing system.

— the system for automatic product level control;

—#nbspautomatic pressure control system;

— automatic washing system.

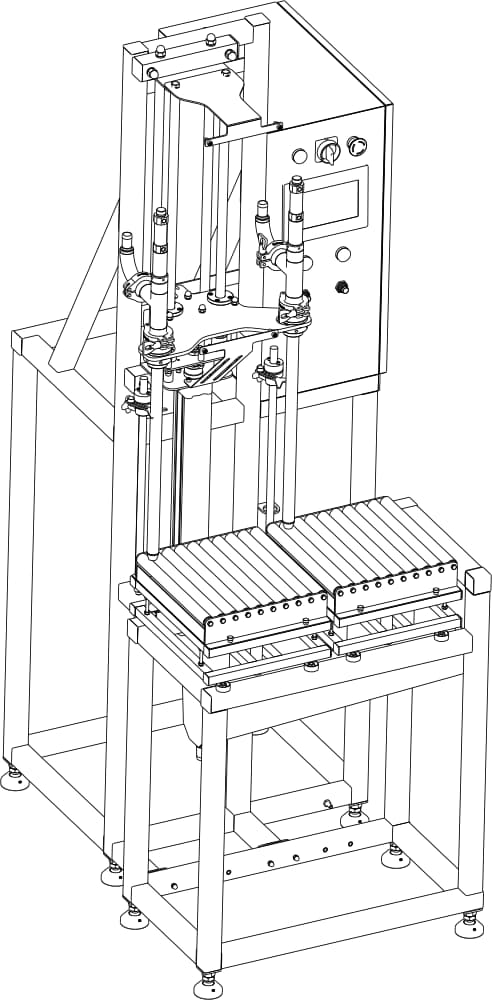

DROP CATCHER

prevents the product from getting on the outside of the container.

NOZZLE LIFTING MECHANISM

is designed based on a pneumatic cylinder with an encoder Smart Filling / quick changeover.

SHUT-OFF VALVE

prevents the product from dripping after finishing dosing / quantity 1 to 2 pcs, material Ti or AISI 316.

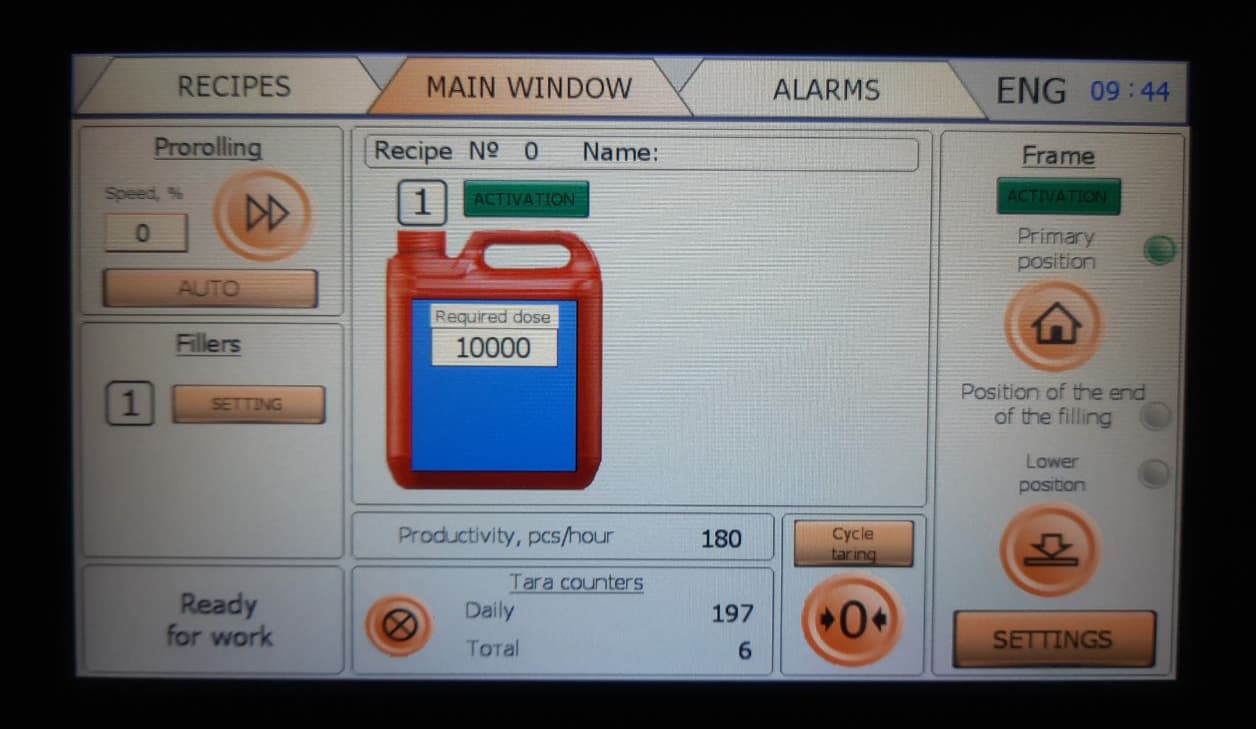

CONTROL PANEL

is based on a touch panel with an intuitive interface.

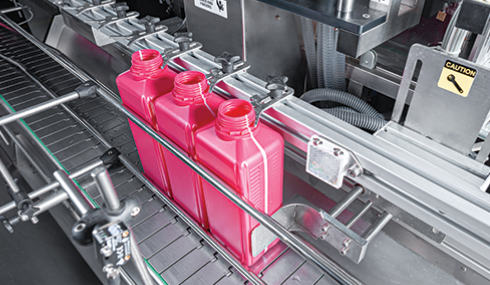

CONTAINER ORIENTATOR

provides automatic orientation of the container neck towards the nozzle

— Krohne or Endress+Hauser flow meter;

— by mass;

— by time.

— by mass;

— by time.

DOSING UNIT

TECHNICAL CHARACTERISTICS:

is used for dosed filling of liquid products into consumable containers.

Method of dosing:

— Coriolis flowmeter / electromagnetic flowmeter;

— by mass;

— by time.

Capacity (on water): bottles/min. up to 15 (500 ml)

Dose volume: 100-20,000 ml

Dosing error:

— by flow meters ±0.5%

— by mass ±0.5%

— by time ±1.5%

Compressed air pressure supplied to the line: 6-8 bar

Maximum compressed air consumption: max. 600 l/min.

Power grid parameters:

— voltage: 220 V

— frequency: 50 Hz

Power consumption: max. 500 W

Overall dimensions: L4000xB1600xH2500 mm

Filling unit weight: max. 1000 kg

Material of the parts in contact with the filling product:

AISI 304, AISI 316, PP, TI, PA, NBR, PVC.

— Coriolis flowmeter / electromagnetic flowmeter;

— by mass;

— by time.

Capacity (on water): bottles/min. up to 15 (500 ml)

Dose volume: 100-20,000 ml

Dosing error:

— by flow meters ±0.5%

— by mass ±0.5%

— by time ±1.5%

Compressed air pressure supplied to the line: 6-8 bar

Maximum compressed air consumption: max. 600 l/min.

Power grid parameters:

— voltage: 220 V

— frequency: 50 Hz

Power consumption: max. 500 W

Overall dimensions: L4000xB1600xH2500 mm

Filling unit weight: max. 1000 kg

Material of the parts in contact with the filling product:

AISI 304, AISI 316, PP, TI, PA, NBR, PVC.

ADVANTAGES:

— High accuracy (using Krohne or Endress+Hauser flow meters);

— Smart Filling System quick changeover ( recipe changeover);

— No stagnant zones (using Krohne or Endress+Hauser flow meters);

— Easy washing of the equipment;

— Minimal maintenance, no wearing parts;

— Wide dose adjustment range;

— Wide range of dosed products;

— Intuitive machine interface.

— Smart Filling System quick changeover ( recipe changeover);

— No stagnant zones (using Krohne or Endress+Hauser flow meters);

— Easy washing of the equipment;

— Minimal maintenance, no wearing parts;

— Wide dose adjustment range;

— Wide range of dosed products;

— Intuitive machine interface.

SEMI-AUTOMATIC MACHINE SMART